|

What is the Electrochemical Machining Process ? |

|

|

| The process is based on Michael Faraday's Law of electrolysis, which is normally used in the electro plating of metals. | ||

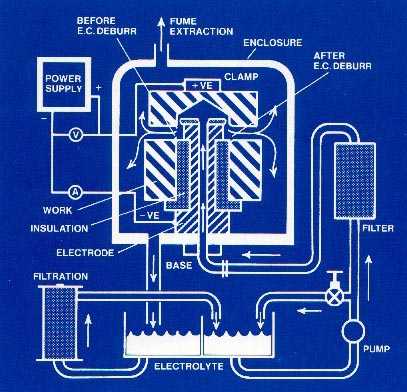

| Electrochemical machining is the reverse of plating, the work-piece is made the anode, which is placed in close proximity to an electrode (cathode), and a high-amperage direct current is passed between them through an electrolyte, such as salt water, flowing in the anode-cathode gap. | ||

| Metal is removed by anodic dissolution and is carried away in the form of a hydroxide in the electrolyte for recycling or recovery. | ||

| A major advantage of electrochemical machining is that it can be used as a de burring or machining process on any metal, no matter how hard or corrosion resistant it is, without creating any residual thermal or mechanical stress in the work-piece. | ||

| The ECD process is illustrated in the panel on the right. |

|

The ECD process produces smooth, burr free edges and ECF can produce smooth, three dimensional forms with a good surface finish in single plunge forming pass. The process is simple to operate and offers fast production rates for difficult to conventionally machine alloys, with low running and tooling costs. |

|

| ECM does not create any physical or thermal stress during machining and components may be machined either before or after heat treatment. Metal removal rates are approximately 60 cubic mm per minute per 1000 amperes DC current employed. Surface finish may be less than 0.4 microns for some materials. | |

|

ECD Machine |

|

| Otherwise difficult to conventionally machine alloys can be easily machined or de-burred by ECM. |

|

|

Examples include the stainless steels, high

performance and high temperature alloys such as Inconel, Rene, Hastelloy, Titanium, Waspalloy and the latest generation corrosion resistant nickel alloys such as 617 and Alloy 59. ECM is an environmentally friendly way of machining, as eroded metal is captured within the machining system as a hydroxide suspension in the working electrolyte. The process offers a lower carbon-footprint than more conventional machining methods and eroded metal can be recovered from the electrolyte in the form of a hydroxide cake which is subsequently treated to recover valuable metal alloys |

|

|

Plunge ECM machine |